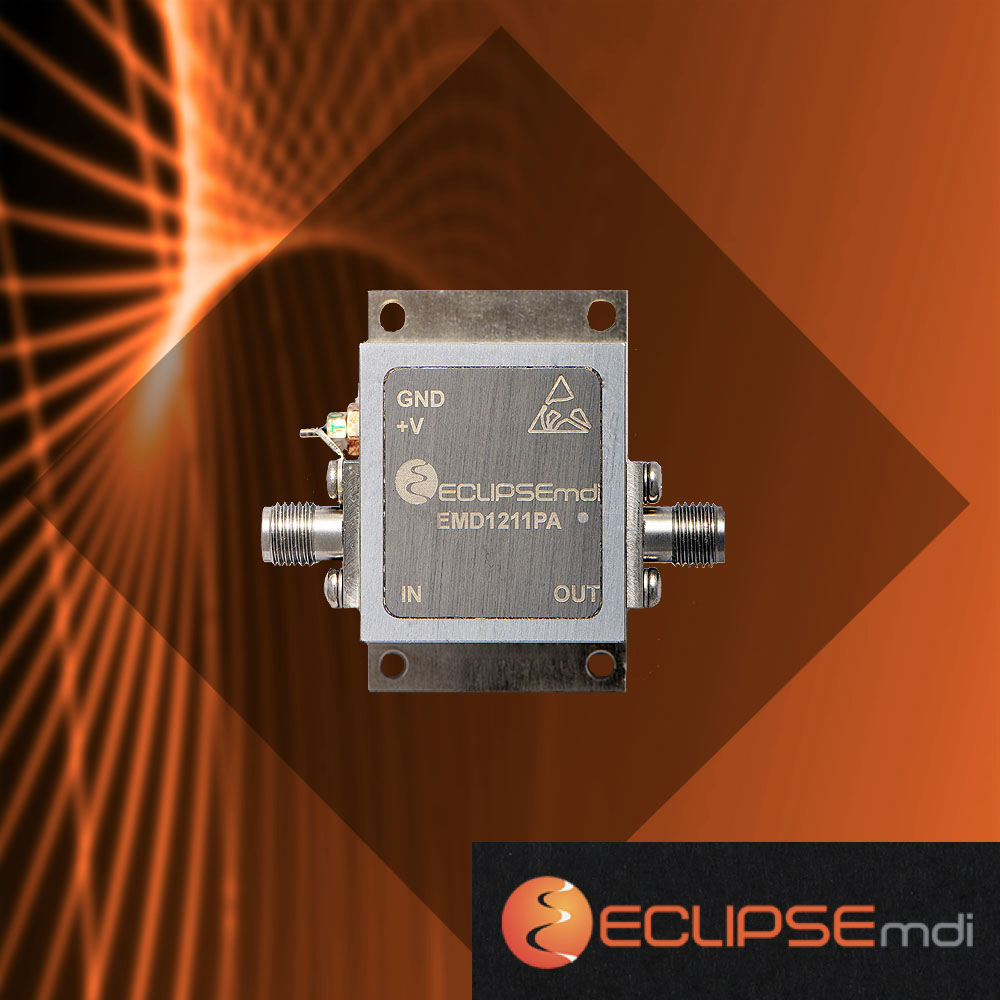

Labeling and ECOs

While working at Eclipse MDI, I was responsible for following clean lab procedure while operating a laser engraving printer to label and quality assure serial numbers on semiconductor and microwave devices including power modules, frequency doublers, mixers, detectors, limiters and amplifiers. I also completed Engineering Change Orders (ECOs) using AutoCAD to clean and update detailed drawings in order to meet new dimensional sheet protocol specifications and clarify directions for fabrication

Quick Details

Fixture Design

While working at Eclipse MDI I was approached with specific problem our CEO was facing. All of the tunnel diodes produced by the company required their leads hand cut. Not only was this process time consuming and inefficient, it allowed room for human injury and error. To solve this issue, I invented and led design of a fixture that could efficiently and accurately cut tunnel diode leads with ease. I then presented this final fixture design to the CEO and Executive Staff.

- Role: Mechanical Engineering Intern

- Hardware: laser engraving printers

- (one for metal and one for plastic)

- Platforms: AutoCAD

- Time Frame: 4 months

- Supervisors: Jeff Rapadas