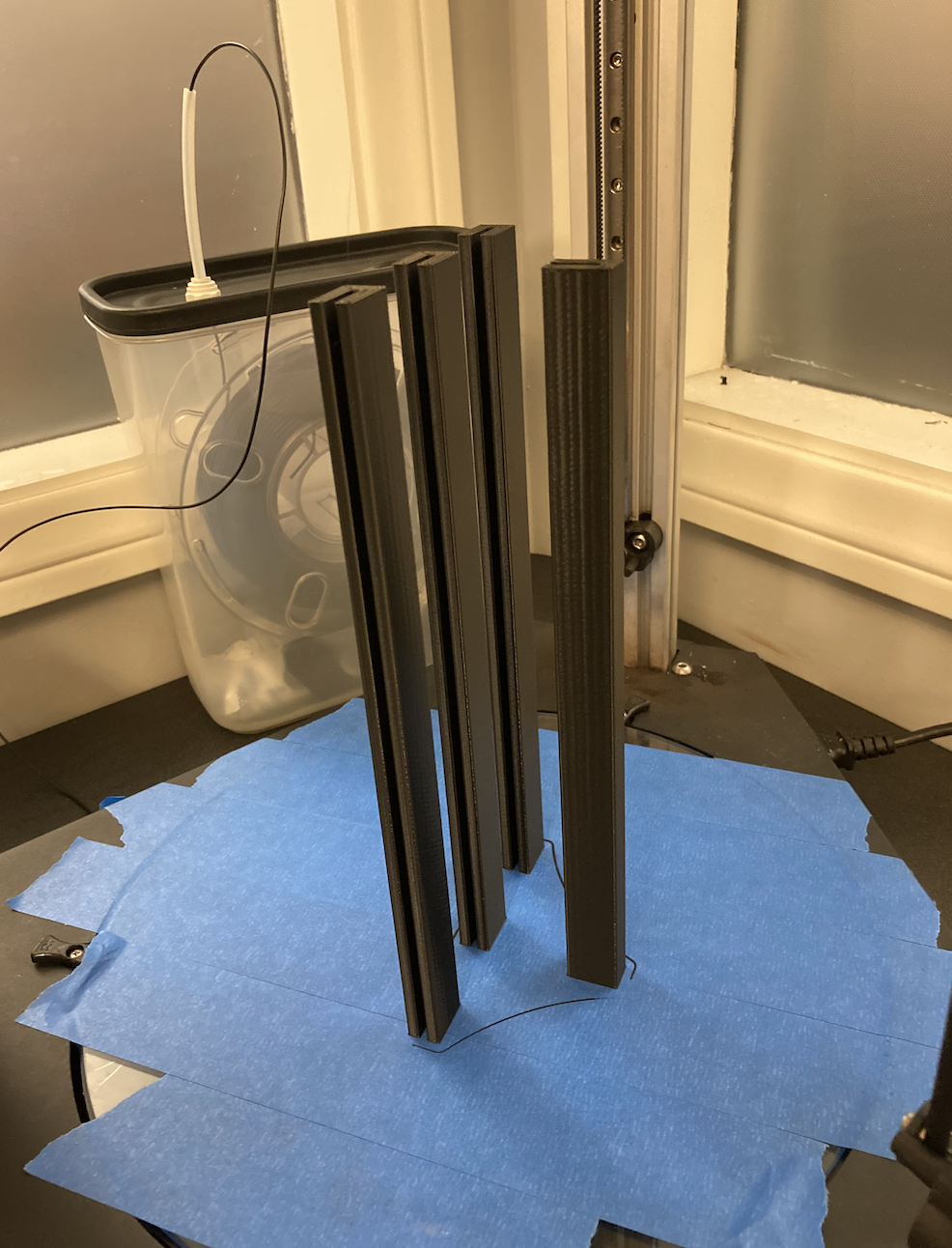

TPU print in progress

Quick Details

At K2 Systems I worked on several projects in both independent and collaborative settings, and with real opportunity to influence future products and company direction! While at K2 I honed my skills in modeling with SolidWorks and 3D printing with various materials. I also learned a bit more about research within the industry and end to end product development.

- Role: Product Development Engineering Intern

- Platforms: SolidWorks, Cura, Artemis 3D printer

- Supervisors: Tyler Wiggins

- Ryan Hagen

- Mireya Roberto

Responsibilities

While working at K2 I designed, printed, and rigorously tested a multitude of products.

TPU print results

Press fit

CNC safety enclosure

CNC safety enclosure 3D printed latch and door

PLA Print